Stepping Inside to Discover Geospatial Frontiers

- Yavuz Eren

- 11 Eyl 2023

- 4 dakikada okunur

Güncelleme tarihi: 12 Eyl 2023

A good friend of mine is approaching the midpoint of a four-year effort to implement ERP at a manufacturing facility specialized in outdoor furniture (personnel of nearly 150). For the past year or so, most of our conversations about this process involve a variety of stories most of which can be symbolized with an image of running head-on into a brick wall. Regardless of these challenges, his confidence with regards to the benefits of setting up an ERP has not wavered.

The difficulties associated with setting up and maintaining an ERP is not limited to midsize enterprises but can manifest itself at different phases even at large firms with the resources to allocate a dedicated IT team. The excellent Tech Trends by the Deloitte institute refers to this issue in their 2021 report, under the section on “Core Revival”. An essential argument put forward in this section is the difficulty of keeping a legacy ERP in tune with the everchanging business strategies and other institutional requirements. Couple of interesting case studies illustrate an updated approach which is summarized as follows:

“What used to be a simple all-in-one ERP suite, or an individual core module is becoming a decentralized, cloud-enabled, API-orchestrated collection of capabilities made cohesive by a simplified user experience.”

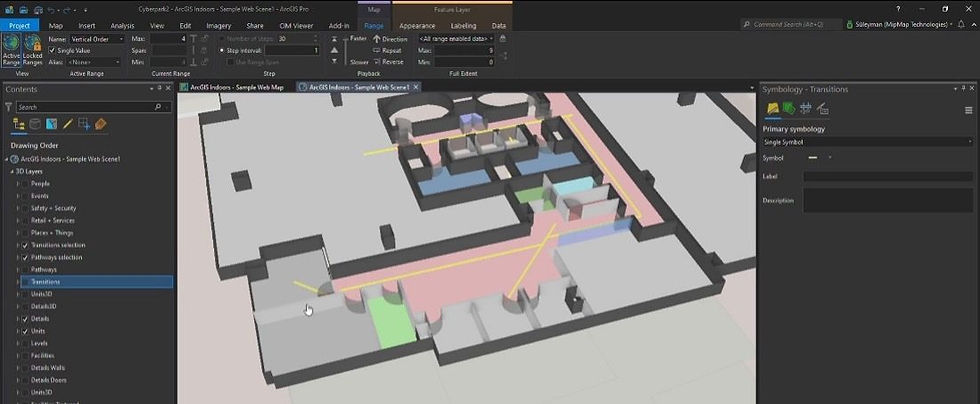

I believe this powerful approach can be taken to the next logical step if we replace “simplified user experience” with “innovative common operating picture” (an expression based on ArcGIS Indoors [DH1] value proposition). Perhaps the first thought that comes to mind for a common platform would be the ERP, which forms the backbone for most large firms yet there are examples in other domains with success stories where a different operational platform was selected as the primary entry point.

One such example is the successful implementation of GIS in revitalizing the Rotterdam Port[SÖ2] . Despite being Europe’s largest port, authorities at Rotterdam realized an urgent need to implement modern solutions for increased productivity due to the space related limitations of their geography. A critical decision was made to combine multiple legacy systems covering the various needs of the port such as tracking crates, land transportation and so forth through a common GIS portal. Considering how natural it is for us to picture tasks or daily workflows through the related locations, one can imagine such an approach would make it easy for different stakeholders to integrate more efficiently through what is essentially a smart map of the port. This transformation has resulted in a significant 15% increase in throughput with further room to grow towards reaching their 2030 goals.

We should not really be surprised by the integration potential of locations; in a way we’re hardwired to create more powerful relationships when locations are involved. For example, the seemingly impossible task of memorizing the order of a 52-card deck involves creating symbolic relationships with landmarks across a familiar route and reimagining a walk across the same path in order to recall each card in the correct position.

Such advantages also extend to the ease by which locations can make multi-layered data more accessible. To illustrate this point, first imagine searching for a book in an online environment. This essentially involves searching for the specific title and retrieving the results with perhaps a sprinkling of similar titles as recommendations. But carrying on a similar task in a physical library provides a variety of rich data such as stacks of unrelated books which might still catch our fancy, a poster on the side for an upcoming event, a person of interest who is also perusing the same area, some over-stocked titles or empty shelves which may give us an idea of current trends. Of course, this is not to say that we can freely stack data on top of a location-based interface; like music, which can accommodate multi-layered sounds within certain rules, spatial multi layered data should include some form of intelligence in ensuring harmony and usefulness.

Going back to the beginning, I had a chance to discuss these ideas with my friend. On the factory floor, the way certain products move from one station to the other overlaid with some metadata with regards to supplies or personnel, can provide a very rich picture of interacting processes and potential choke points. These would likely be hidden by a traditional dashboard focusing on a specific problem or a query. The combinations are endless: a smart floor plan showing the flow of semi manufactured parts clustering around a paint station could indicate the need for additional help, overstocking at the warehouse could be predicted when we have a bird’s eye view of production flow and so forth.

There are many scenarios in this domain and others such as hospitals and university campuses that we will develop over the upcoming months using ArcGIS Indoors and our proprietary solution Evolved.City, thus this piece is not a musing on what could be but it’s a road map. We are very excited about this journey and would be happy to share our experiences and hope that you will join us from time to time and provide your feedback on this new way of approaching facilities and geospatial technologies.

Yorumlar